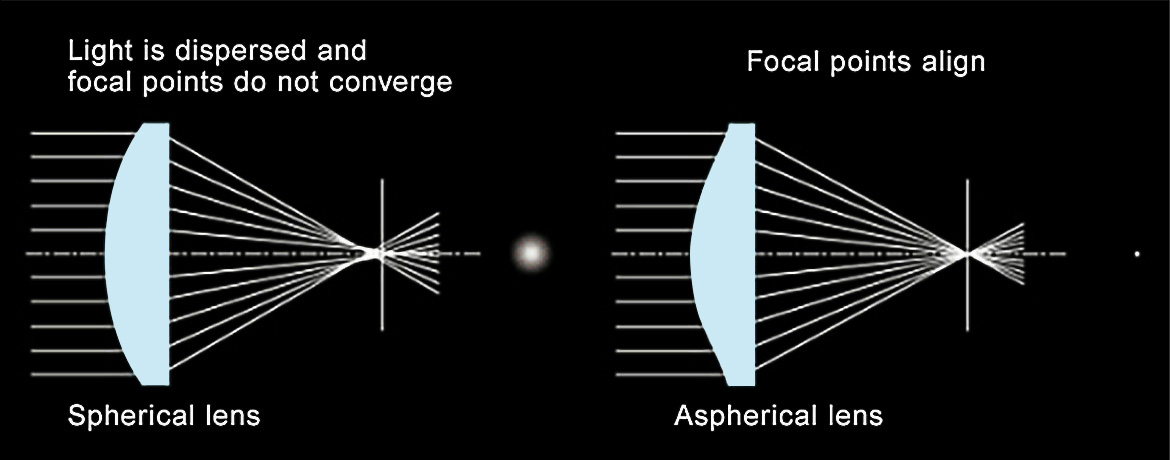

Another type of special lens elements is the aspherical lens. Canon’s L-series lenses owe their high performance and crisp image resolution to these specially processed lenses, which offer truly revolutionary optical characteristics. Aspherical lenses offer impressive sharpness and vivid detail that it almost seems like a veil has been lifted to reveal the visible world behind the lens. For years, aspherical lenses were only a dream for optical engineers, since their actual fabrication is so difficult. Aspherical lenses differ from conventional photo lenses — which are spherical — as a part of the spherical surface of the lens element has to be cut away at the optical axis. However, these lenses faced theoretical limitations due to their inability to converge parallel rays of light at the same focal point. The solution was to fabricate an aspherical lens with an ideal curvature, which converges parallel rays at a single focal point.

In some aspherical lens designs, the degree of asphericity is very slight. To the naked eye, it appears identical to a spherical lens. The degree of curvature is so slight that precision processing tolerances must be calculated to within 0.1 micron (1/10,000th of a millimeter). Though certain issues relating to mass production had not been completely resolved, at the time, Canon introduced the FD55mm f/l.2 AL in 1971. It was the world’s first SLR camera lens (without mirror-lock mechanism) to incorporate a ground aspherical lens element. Ground aspherical lenses are type of extremely high-precision aspherical lenses that are shaped to perfection by grinding and polishing individual pieces of glass. This type of processing can be applied to various types of glass, and allows the manufacturer to produce aspherical lenses with large diameter and large displacement from the spherical surface. The strong reception this lens received prompted Canon to increase production volume and accelerate aspherical lens research. Just two years later the company was able to introduce that the world’s first nanometer-class mass-production equipment (with tolerances of less than one-millionth of a millimeter).

The lenses are polished precisely to a precision of just 0.02 micrometers, which is just 1/32 the height of a wavelength of visible light. This exacting precision ensures that the lenses will deliver high optical performance that one can only find with the L-Series.

Aspherical lens manufacturing technology continued to evolve. In the 1980s, research and development of large-diameter glass-molded (GMo) aspherical lenses began, and in 1985 these elements were successfully put to practical use. Glass molding technology uses high-temperature melted glass and aspherical, high-precision metal molds, to achieve superior surface tolerances. In 2007 the technology was used to make the first concave aspherical lens. The same technology has been used in many of today’s RF L-series lenses.

One Canon aspherical lens that satisfies a variety of needs is the replica aspherical lens, which was developed for the EF lens series in 1990 and is characterized by a high degree of design freedom in terms of the size, and the type of material used to make the spherical base lens element. In the RF lens series, the RF24-105mm F2.8 L IS USM Z also uses a replica aspherical lens. Improvements in the manufacturing process have given replica aspherical lenses a surface precision superior to that of EF lenses. In addition to offering greater freedom in optical design, the size of the new lens has been reduced while providing a focal length of 24mm-105mm with consistent performance at a bright aperture of f/2.8.

High-temperature melted glass and aspherical lenses.