Paper Specifications - Fine Art

Paper Specifications

Besides paper type, there is an array of information that helps in choosing paper.

The following explains some of the terminology used in catalogs and websites.

- Whiteness/paper base tint

- Thickness/base weight

- Surface quality

- Density range

- Instant drying characteristics

- Storage stability/weather resistance

For detailed information on how to handle print papers, see the instructions on the package of the paper.

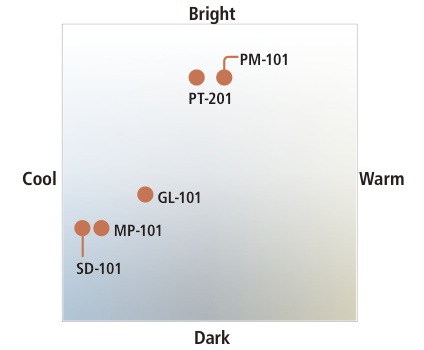

Whiteness/Paper Base Tint

The brightest area in a print is where there is no ink on the paper. Whiteness of paper varies widely, including bright white, dark white, and yellowish white. An indicator of whiteness of paper is ISO Whiteness (expressed in %). For example, taking 100% whiteness as the maximum, the ISO whiteness of newspaper is about 55%.

Papers that are very white and less biased in terms of color tone reproduction can reproduce natural color tones and vivid colors. To improve the whiteness of paper, the addition of barium sulfate (Baryta) or fluorescent whitener is required. Storage stability may vary depending of the type of additive contained. On the other hand, there are some types of papers that are not treated with a whitening process in order to make the most of their original texture.

Thickness/Base Weight

Thickness and weight of paper are closely related to whether the paper feels luxurious when touched and how stiff it is. Thickness is indicated in micro meters (μm) or millimeters (mm) in general (e.g., 300, 300 μm, 0.30 mm), while weight, or base weight, is expressed in terms of grams per square meter (e.g., 300, 300 gsm).

Heavier paper of a certain thickness is stiffer and harder, so you need to check if the printer’s paper feeder can handle thick paper.

Surface Quality

Surface quality describes whether the surface of the paper is rough or not and whether the paper is glossy or matte, among other factors. Papers that reflect light are classified as glossy, papers that slightly diffuse light are called semi-gloss, and papers that minimize reflection are categorized as matte. Depending on the difference in the quality, papers are further differentiated as platinum, high gloss, pearl, satin, and so on.

Papers with a flat surface are called smooth, while papers with very rough surfaces are called rough. Matte and rough papers show the original characters of the paper. Smoother and glossier papers can reproduce the colours in the photograph more straightforwardly.

Density Range

One way to make the sharp black of photographs deeper and richer is to layer multiple inks other than black ink. Higher ink concentration and sharper blacks improve the contrast of the entire photo, enhancing its distinct impression. When you use an ordinary type of paper, however, the more inks you use for printing, the deeper the inks penetrate into the paper and run. That may result in problems, such as reduced colour density or poorer definition.

Fine art print papers retain as much ink as possible on the ink absorbing layer coated on the base paper in order to prevent ink running and improve colour saturation and density.

Instant Drying Characteristics

Ordinary inkjet papers require a certain amount of time until color saturation stabilizes after the processes of printing to drying. It sometimes takes a while to create multiple prints for color adjustments.

The amount of time required for a print until it stabilizes varies between dye inks and pigment inks, and also depends on the type of paper used.

Storage Stability/Weather Resistance

In the case of photographs that you want to keep on display year after year, it is crucial to minimize colour fading over time (deterioration with age). While users need to be careful in printing and storing, some types of papers are made with due consideration to fading.

A print is a compound of paper and ink (colouring material). Colouring materials fade due to weathering caused by gas in the air and light. In terms of deterioration of colouring materials caused by gas, the chain-reaction deterioration of colouring materials caused by light via oxygen, and further chain reactions of deterioration factors that occur during the deterioration process, additives that prevent deterioration can be used in the ink colour reproduction layer to minimize fading of colouring materials.

If you wish to store a print work for a long period of time, thoroughly dry the inks and put the work in a glass photo frame to block air contact to some extent, and hang the frame avoiding direct sunlight to delay possible deterioration and fading.